The Research & Development that sets us apart

Learn more

The Research & Development that sets us apart

Here at Sealy, research and development are at the heart and soul of what we do – that’s why we continue to invest in our state-of-the-art Research and Development Centre (R&D Centre), which allows us to deliver Sealy Sleepers supportive, comfortable, and durable mattresses that stand the test of time.

Research and Development is the foundation of all our products. Ten years ago, we began our journey towards building a specialised R&D Centre. Initially, we only had a few testing capabilities that were managed by a small team. Today, that same team has grown from strength to strength – not only allowing us to develop our capabilities as we established new functional areas, but also house even more crucial testing machines, leading to patented machinery and sleep technologies.

With this vision in mind, in 2021 we opened a new global Research and Development Centre to enhance our scientific approach to product development. Within 2021 alone, over 4000 tests were completed at this facility, it’s this data collection and analysis that allows us to set the benchmark for product quality so high and use advancements in science, technology, and engineering to further our knowledge.

“It is about inventing and innovating the new, improving and evolving the current, and making sure it is all built on a real and technical foundation.”

– Daniel Green, Research and Development Manager.

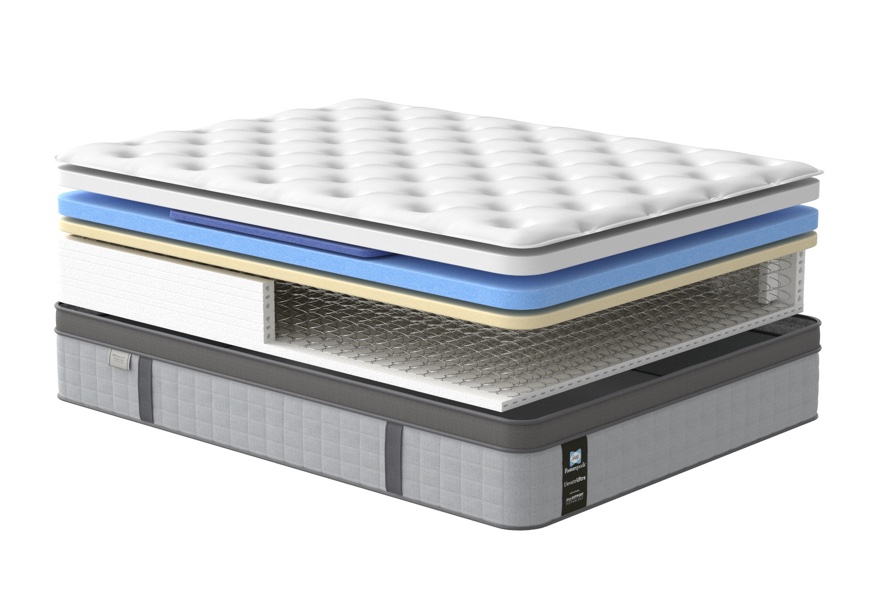

It’s what is inside that counts

Our R&D centre houses a ‘mini factory’ in which 32 machines are busy running 68 carefully curated tests, from the initial durability testing of each raw material, all the way to the final testing of the finished constructed product. These tests are carried out so that we can create mattresses that deliver Genuine Support, True Comfort, and Durability you can depend on.

Our R&D team analyse the results from this testing, and use it to inform product development; encompassing everything from the fabrics that make up the product to its looks, to how the comfort layers are arranged, as well as creating prototypes, and ensuring that every aspect of the product meets and exceeds international testing requirements.

Types of Testing

The Load Deflection Analyser (LDA)

The Load Deflection Analyser (LDA) is a critical part of our testing regime. It measures the height and firmness of a mattress before and after any test we do. This allows us to analyse the durability of our products before and after every test, to ensure that the mattress will withstand whatever life may throw at it.

Cornell Tester

The Cornell tester is a real game changer for us, it is fully automated and is truly world’s best practise. The machine allows us to run additional testing of edge and mattress durability by firmly applying pressure on the mattress, allowing us to test the durability of the final product.

Climate Lab

We understand that body temperature is an important comfort consideration when choosing a mattress – no one wants to restlessly toss and turn during the night. We use a Climate Lab with machines that precisely imitate the experience of sleeping on a Sealy Posturepedic mattress. Through advanced testing, we discover the benefits and differences new cooling technologies will have on your overall sleep.

Robot Durability Testing Device.

This test is just one of many clever technologies created and patented by Sealy. The Robot Durability Testing Device is a precision machine that really puts a bed through its paces by simulating a real wear and tear test. After measuring the height and feel of the ensemble in a few locations, the robot swings into action. It mimics user behaviour by sitting on the bed edge and sliding to the centre. It will then lie down, before sitting back up and sliding back to the edge of the bed and standing up – this can be programmed to repeat thousands of times! At the end of the test, we measure any difference in the height or feel of the product and look for any breakages that might have occurred.

Fabric Testing

Within the R&D Centre is our fabric testing room in which our Designers carefully consider the texture, design, colour, composition, and quality of fabrics when creating our mattresses. The fabrics and textiles have been expertly designed and selected to stand out and ensure a clean and comfortable night’s rest.

Find your next Posturepedic mattress here